Gusu Machinery ofrece una variedad de máquinas atemperadoras de chocolate, que van desde 10L hasta 2000L, adecuadas tanto para la producción de chocolate artesanal a pequeña escala como para aplicaciones industriales.

1) Templadora de chocolate pequeña de 10 litros

esto máquina de templado de chocolate está diseñado para derretir el chocolate, controlar con precisión su temperatura y mantenerlo en un estado óptimo para promover el proceso de cristalización. Funciona calentando gradualmente el chocolate a aproximadamente 45 a 50 grados centígrados para derretir todos los cristales de manteca de cacao.

esto model is widely used in chocolate shops, bakeries, pastry shops, and confectionery factories for making shaped chocolates, chocolate-coated products, and chocolate fountain displays. It is also an indispensable tool for bakeries, chocolate shops, or small artisan chocolate makers.

2)Máquina templadora de chocolate 20-50L

esto model is the Gusu Machinery TTJ series chocolate tempering machine, featuring functions for hand-pouring chocolate, tempering chocolate, and coating chocolate. The built-in heating element heats and melts the chocolate, which is then continuously circulated within the tank via a circulation system. Simultaneously, a control system maintains the temperature to the desired level, resulting in improved appearance, better taste, and a longer shelf life.

La máquina atemperadora de chocolate serie TTJ está disponible en capacidades de 20 L, 40 L y 50 L, adecuada para panaderías, cafeterías, heladerías y chocolaterías, plantas procesadoras de alimentos y otros establecimientos similares.

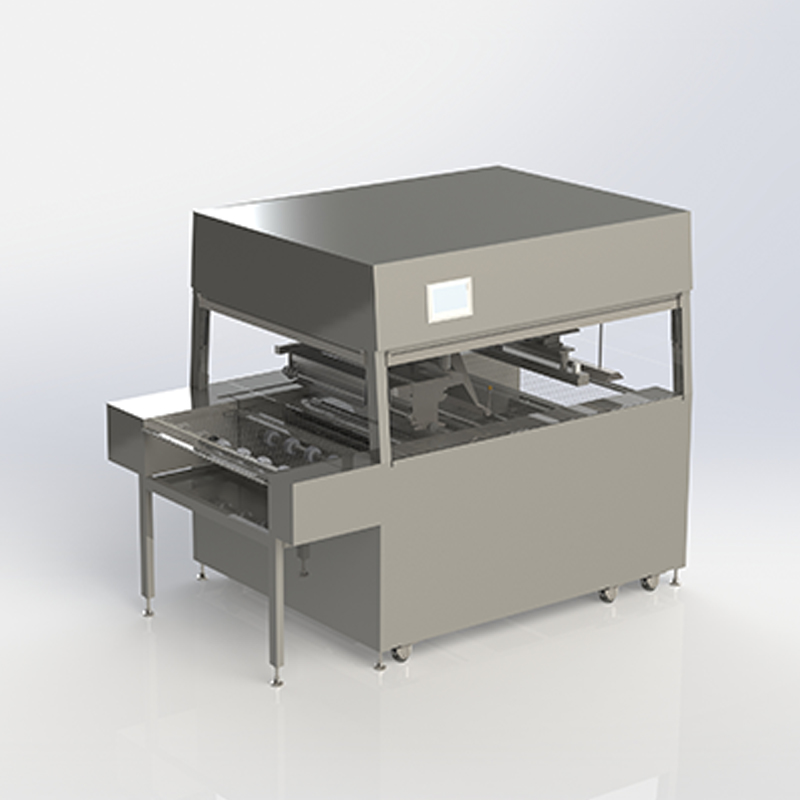

3) Máquina templadora de chocolate de 100-2000 L

esto model is the Gusu Machinery QT series chocolate tempering machine, designed based on the characteristics of natural cocoa butter. It features a vertical structure; chocolate raw materials are fed in from the bottom via a chocolate pump, then pass through four temperature-regulating zones and one constant-temperature zone before exiting from the top. This series of processes results in chocolate products with excellent crystallization, a smooth texture, outstanding shaping properties, and a longer shelf life.